Our team ended up with a bunch of rounded 1/16" Aluminum 2x1s, which we wanted to use on the siderails of an offseason west coast drive. Would there be anything against using rounded tube in this application?

What kind of bearing blocks (if any) do you use for your WCD? A clamping one like TTB or VEX’s may not play well with 2x1 tubing with too large of a rounded corner (no material to bite onto).

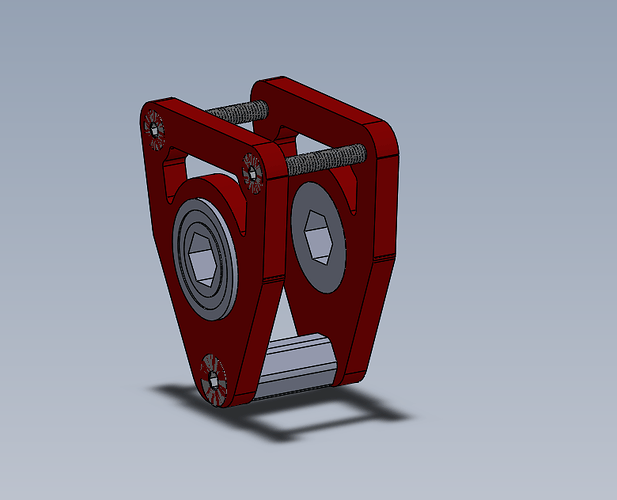

We’re using custom 971 style clamping bearing blocks like the ones in the picture, but we are using 1/8" 2x1 for the driverails and the rounded tube for just the siderails (or front and back rails), would they be fine for that application?

I don’t see anything at first glance that would make me say they wouldn’t work in that application.

(Aside from my inner self screaming that things don’t match, but that’s literally zero reason not to use material you have access to if it’ll help you budget for other parts down the road. Lol)

IIRC is will make chain in tube annoying/impossible depending on the radius, but I would like to think the world has moved on from CiT.

Why do you think the world has moved on from chain in tube (just curious), less space constraints maybe?

Cost-benefit

Costs: space, time, special sprockets, increased difficulty to repair (though unlikely to break)

Benefits: like 1" more space inside the robot frame, protection from carpet debris

Additional cost: it’s not a COTS swerve. Pretty much every team out there enough to do CiT is now running swerve.

We use chain in tube quite happily. Keeps the wires away from the chain, super lightweight, in our latest version we are around 25lb for a complete drivebase with electronics. We also have swap-able drive rails so we can keep spares are rebuild them at our leisure.

Highly recommended to anyone not jumping on the swerve train.

What sprockets do you use for chain in tube?