Outreach Log, Week 1

Hello everyone! In the spirit of the Open Alliance, our team has decided that, going forward, we will be updating this blog with our outreach- and awards-related progress in addition to our build season progress (albeit at a slower rate than our build blogs). We believe it could be of some use to both ourselves and teams with less awards experience to share our progress in composing our submissions and making our pit binders. For this first post, we’ll be going over our team’s circumstances and our work during the off-season in addition to our awards progress thus far. We hope you appreciate this additional insight into our team during this build season!

- Vaani Mathur, Outreach Director

Our Current Circumstances

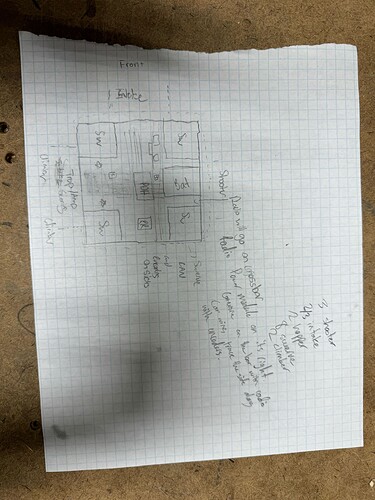

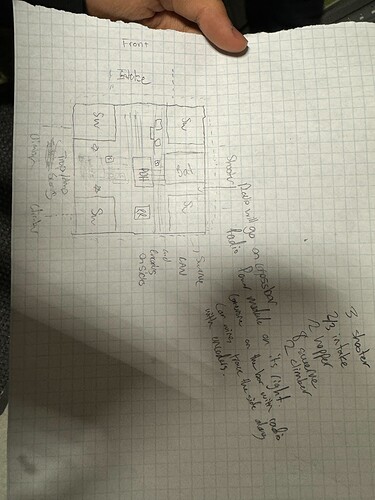

Our school district has a designated building, the Robert Shaw Center for STEAM, meant for all of its high schools’ teams to both build their robots and practice on a full-sized field (our fellow teams include 624, 2882, 5427, 6488, 8370, and 8576). Each team has access to their own bay with a larger workspace at the front and a small machine shop at the back; additionally, a communal machine shop with larger machines (including a mill) is located at the back of the building. The RSC is also the host venue for the majority of our team’s in-person camps as well as STEAM Nights organized by the district. The RSC not only gives us the ability to design competitive robots but to conduct larger-scale outreach events and collaborate with other teams.

Our team also has a number of corporate sponsors, the majority of which we have gained from parental connections and one of which we even gained from one of our elementary school demonstrations. A new sponsor - Honeywell - that we acquired this year has set ourselves up with a higher budget than usual going into this season; this was very beneficial as we will be participating in our first travel tournament (FiT Dallas) in about 2.5 years.

Off-Season 2023

Over the past off-season, spanning from last May to the end of the year, our team has hosted camps, connected with sponsors (both old and new), held our annual off-season tournament, mentored FLL teams, and recruited and trained new members.

Camps

Since 2019, our team has hosted a variety of camps both over longer school breaks and on various weekends throughout the school year. In 2020, we were forced to move all of our camps online, and, since then, our team hosts a mix of online camps, in-person camps held at the RSC, and in-person camps held in outside venues in cases where the RSC is closed. The location largely depends on the topic being taught; for example, our Web Development camp was held online while our STEM camp was held in person at the RSC. This allows us to get the best of both worlds: our online camps give us the ability to reach kids outside of our local area, and our in-person camps give the kids a hands-on STEM experience. These camps were mainly aimed towards older elementary- and middle school-aged students and, as such, included activities ranging from constructing towers out of recyclable materials and designing balloon cars to learning the basics of Java programming and building websites.

Apart from our paid camps, our team organizes an annual Girl Scouts Robotics Badge Workshop. In our workshop for 2023, Girl Scouts in grades 4-8 learned the Engineering Design Process and utilized it to design their very own robots to solve daily household problems. We are also in the process of organizing a Think Like an Engineer Journey Workshop in February; with these events, we hope to continue to develop our relationship with the local council, the Girl Scouts of San Jacinto.

Sponsors

Our process for gaining new sponsors this year involved first listing out potential STEM-related companies (e.g. Air Products, ConocoPhillips, Markforged), then finding their contact information before sending them a copy of our Sponsor Letter and Sponsor Perks List. Our letter includes information on our typical expenses and our team’s achievements, and the perks include everything from making buttons with their logo to putting their logo on our robot. Our goal with each new sponsor, particularly those gained through parental connections, is to maintain our team’s relationship with them for many years, even after the student whose parent works for them graduates. In order to do this, our team sends out a monthly E-News email going over our accomplishments from the previous month and continues to provide the same perks as when the alum was still on the team. In the near future, we are also thinking of creating weekly vlogs to be uploaded to our YouTube channel to not only be more thorough as an OA team but also to provide higher-quality updates for sponsors.

The Pumpkin Rumble

Since October 2021, our team has held an annual, Halloween-themed off-season tournament, called the Pumpkin Rumble, at the RSC. This event is meant to provide all of us RSC teams with a chance to prepare for the upcoming build season by giving drive teams an opportunity to practice and new members a chance to learn how an FRC event works. Our most recent one also included a costume contest, Mummy Wrap game, Candy-Counting contest, and Human Matches. In the future, we are looking to possibly expand this event to be an official off-season event, but that will require more funding than we currently have available and a facility with a larger capacity. In the meantime, this event is always the highlight of the off-season and is an event all of us teams look forward to every year.

FLL

Our team has been mentoring local FLL teams since 2021 when we started 2 teams at our feeder middle school. About a year later, we started a 3rd team, and these teams have continued to compete for the past few seasons. Most recently, our team started FLL at another middle school in our district, and we have been volunteering at their biweekly meetings. Our team’s vision is to eventually reach a point where kids in our district can follow a path from FLL to FTC and eventually to FRC, all the way from elementary to high school. For now, we are focusing on establishing FLL teams in all of our nearby middle schools.

Our Recruitment & Training Process

Many of our new members are freshmen who learn about our team through our school’s Fish Camp; many other members are told by their friends about the team and join with them. We then hold an official interest meeting in late August (our school year starts mid-August and Fish Camp is about a week before) where we discuss our team’s departments, our schedule throughout the year, and the registration process. Our registration then closes at the beginning of September, and, shortly after, we hold our General Meeting where we go into more detail about the training process and schedule, the hour requirements, and our plans for Build Season. This is also around the time where we have our Parent Meeting to explain the options that parent volunteers have to contribute to the team.

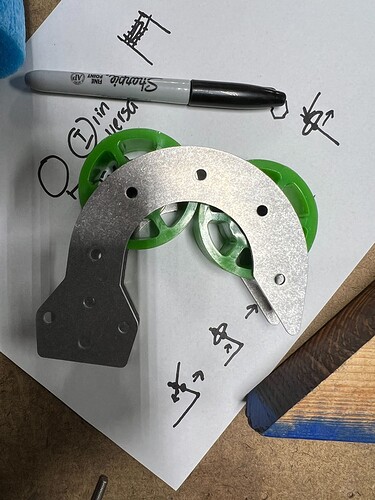

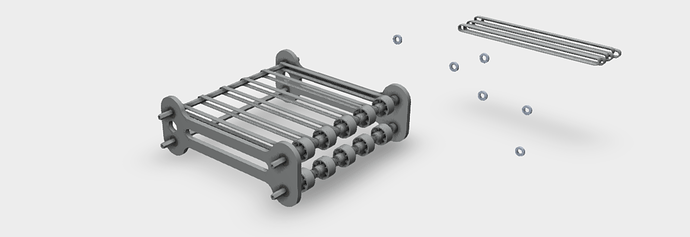

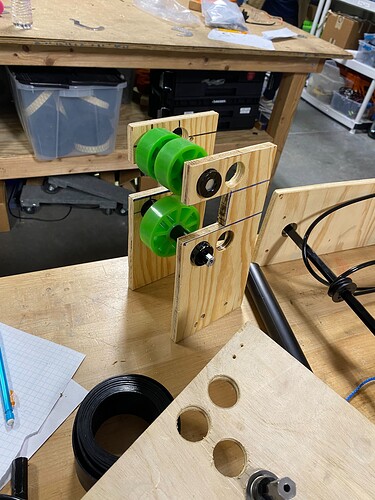

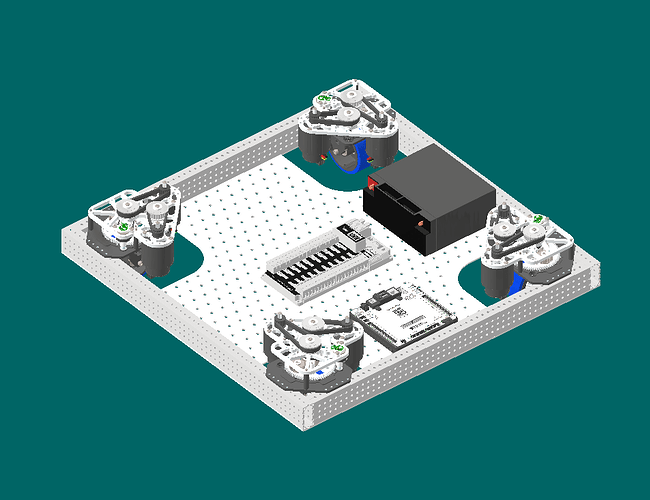

For the next 2-3 months, our build directors train our new members by teaching them about the various components, tools, and machines in FRC and how to use them. We require that all of our members become fully trained in at least one of our five departments (Mechanical, Electrical, CAD, Machining, or Programming). Our training process involves first studying material on our team’s Google Classroom before coming into the RSC to apply that material with hands-on training. We also hold drive team tryouts during this time and require that our members reach a certain hour requirement for volunteering at outreach events in order to be able to attend competitions. This is also around the time when we hold our Mock Kickoff (see the beginning of this thread for more info on that).

Week 1 Progress

At this Wednesday’s weekly outreach meeting, our outreach directors settled on our deadlines for finishing our Executive Summaries as well as our Technical, Outreach, and Financial Statement binders. As FiT Katy has its load-in on February 29th, we decided that we will be sending our binders for printing on the previous Sunday (Feb. 25th), meaning we are aiming to have them finished on the 24th.

In 2022, we earned Engineering Inspiration for the first time, and, last season, we earned Team Sustainability at both of our district competitions. In order to improve our chances of earning higher awards, we’re going to try and incorporate more statistics into our Outreach binder rather than just general descriptions about our events. In order to do this, one of our outreach directors went and compiled data from our past few camps and outreach events. Another one of our directors also did some research on past Impact winners in both FiT (118, 5414, 5427, etc.) and outside of our district (namely 321). We are hoping that studying their submissions and videos will help us to improve our own submissions.

Our Outreach and Financial Statement binders typically don’t need much work beyond updating them with new information and pictures, so we are planning on starting the work on them later into February to allow us to focus more on our Impact submissions, video, and speech.

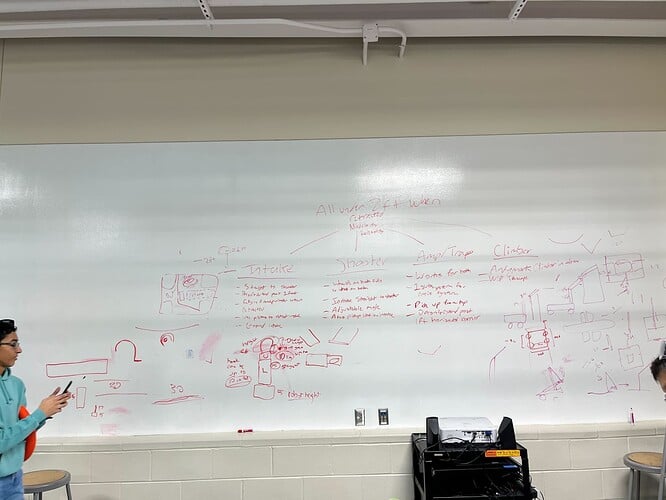

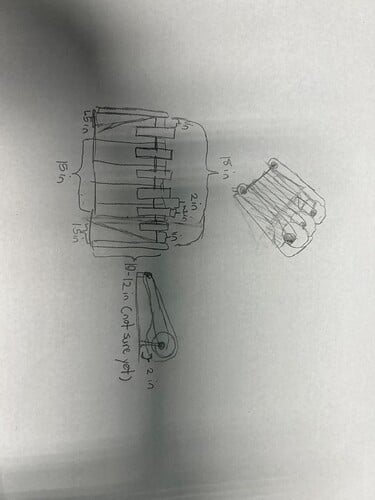

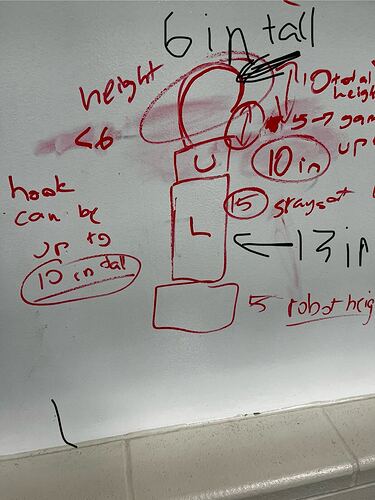

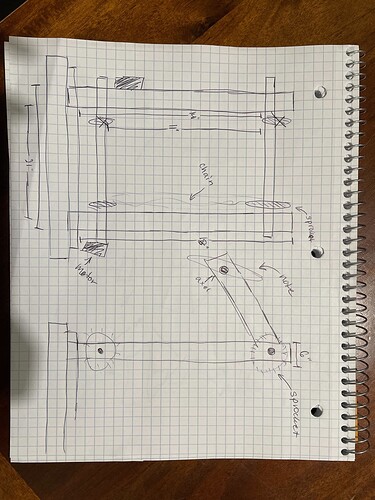

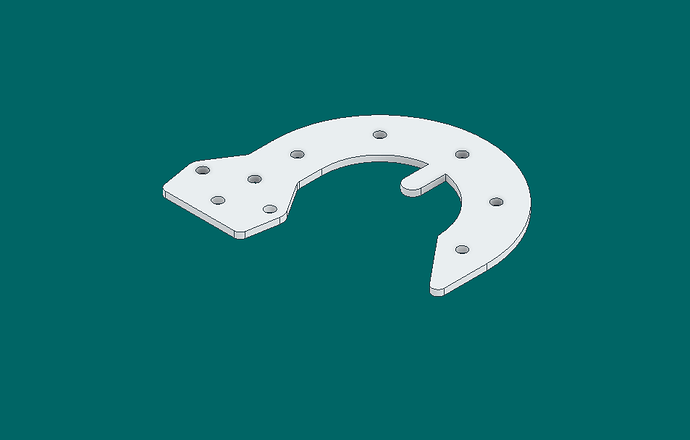

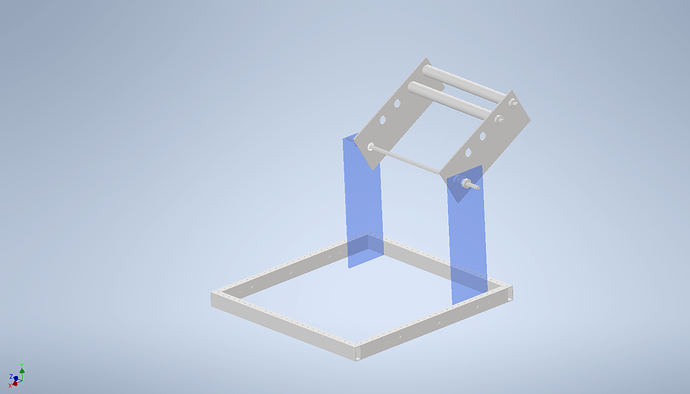

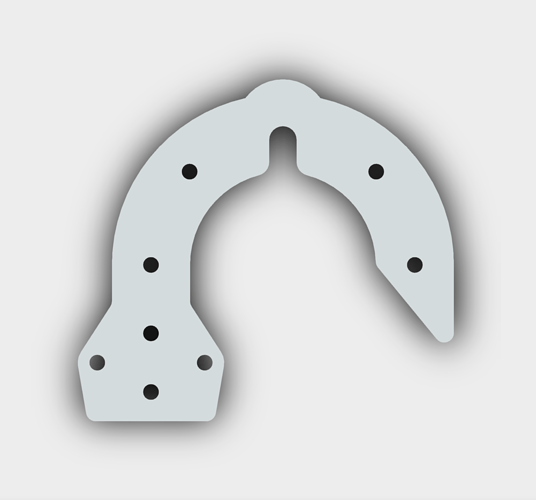

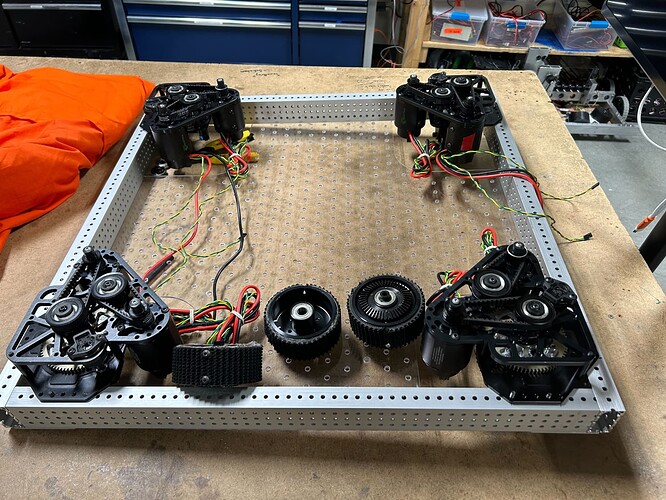

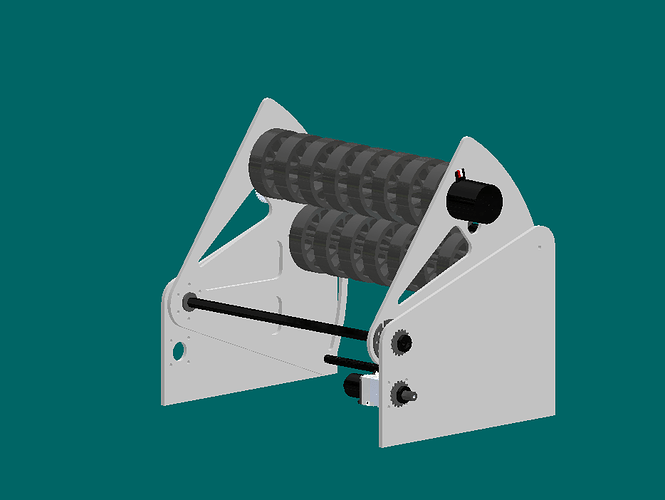

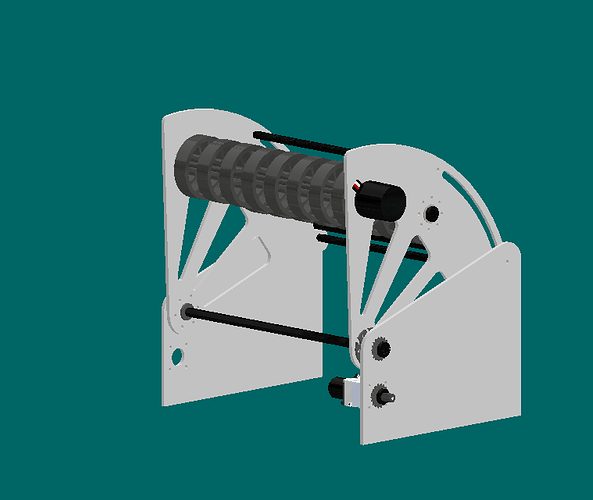

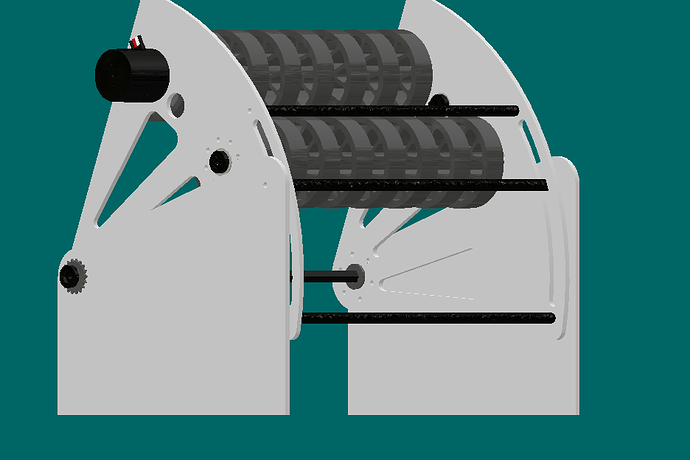

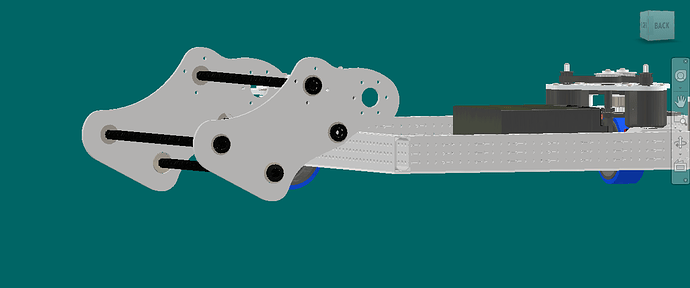

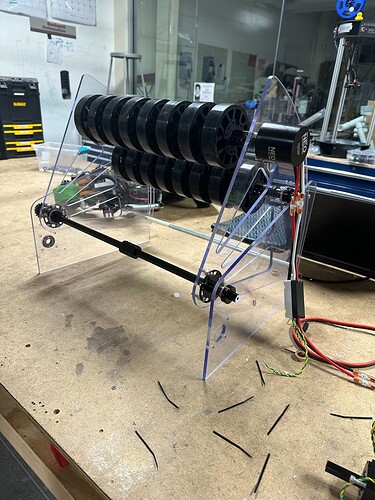

Our Technical Binder, however, will obviously require some more time than our other binders as we will be creating a brand new one for our new robot. We are planning to create a template by the end of next week with a simple layout for all of the subsystems as well as the intro portion. The intro portion will consist of a list of our design priorities and will be followed by a list of our individual goals for each subsystem. When the robot’s design is finalized, we will then add in the CAD for each subsystem and details of the different components we used. As we often iterate on our robot from tournament to tournament, we typically have to reprint this binder with the updated CAD and descriptions.

Outro

That’s all for now, but we will try our best to update this log at least weekly if not more often. We’d appreciate any and all feedback, and we would be more than happy to answer your questions. As always, have a good day everyone, and good luck this season!