WEEK 2

CAD Review

Last week I posted a deep dive into our CAD and design process, so here I go again with what’s changed throughout week 2.

Electronics

We decided to mount the battery vertically within the frame, rather than horizontally on top of the brainpan. This was to make it easier to hold in place during the match, as well as to shift weight downwards and towards the back. It also means changing up our electronics layout, which we’re still figuring out the best solution to. Right now our best options are either to put the PDP between the drive motors, which doesn’t give much clearance for wires, or to put the PDP on the other side of the robot from the battery, which would mean longer wire runs.

Neither of these are ideal.

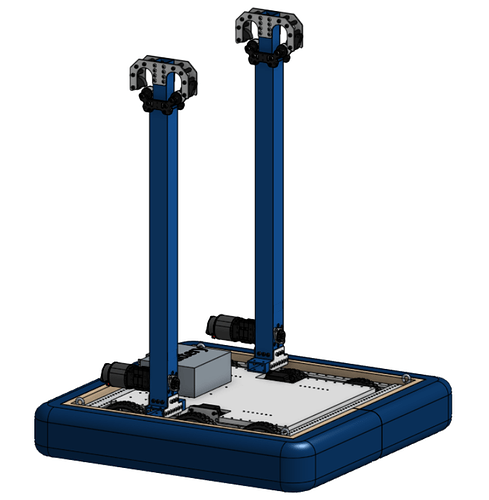

Climber

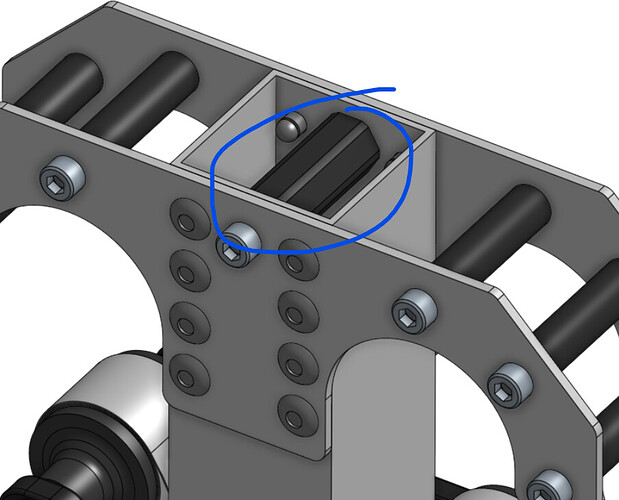

The climber has still barely changed since early week 1, but here’s some more explanation of the mounting system and overall design process:

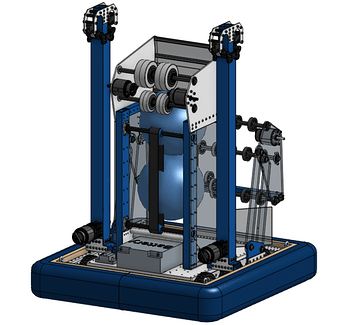

The tubes are held to the drivetrain via a horizontal tube that goes across the drive rails and attaches to the brainpan and drivetrain. This is then attached to the outer tube of the climber using a WCP tube plug, as well as gussets on the sides. Originally, these tubes were one conjoined cross tube, but it ended up getting in the way of the main structure and was cut into two smaller pieces.

On the main tube itself, there are mounting holes for the MAX Planetary on one side, and clearance holes on the other side to access the mounting bolts. There are also holes to attach the 3/16” plate that supports the outer bearing. The MAX Planetary is then also supported by gussets on the sides (shoutout to REV for making it exactly 2” wide!).

An idea that we’re considering is the addition of some kind of bracing between the tubes, similar to the one sold by AndyMark. Since it won’t be too hard to implement down the line, we’ll stick with the current design for now and add it later if necessary.

Within the tube, we switched from our original idea of 3D printed spools to just using the shaft itself as a spool, with shaft collars to constrain the rope. Because of how much disassembly is required to access the spool, we decided that 3D printing just wasn’t worth the risk of failure. This also means we can use a much lower gear reduction on the motor, which frees up MP cartridges for use elsewhere (we currently have only 2 of each size).

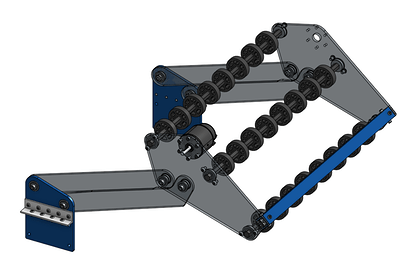

Intake

Barely anything has changed here. The mounting system is now a little less scuffed, with bearings on one side and a 1/4”-20 bolt going through the arms with a nut holding it in. I know bushings would be easier and cleaner, but we don’t have very many - and we do have a ton of these 3/8” ID x 7/8" OD bearings.

I’ve been thinking of ways to put the pivot points a little further apart for increased stability, but it doesn’t seem too big of an issue, and most mounting solutions on the KOP drivetrain are not ideal.

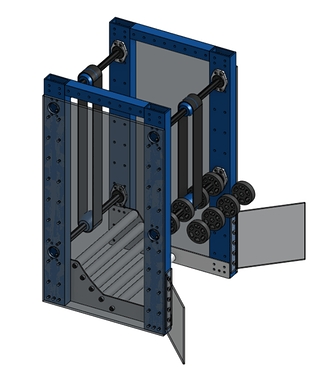

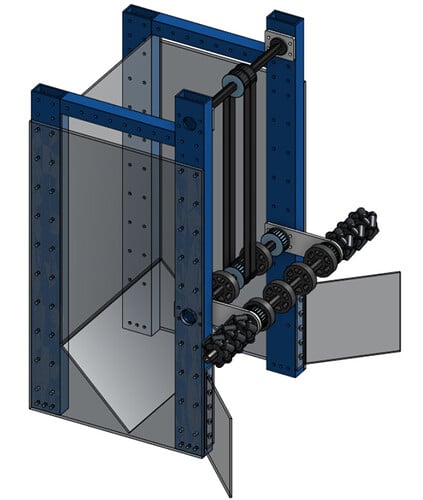

Indexer/Feeder

The feeder has been simplified quite a bit since the first iteration. It went from a double-sided conveyor with PVC rollers in the corner to now just a single set of belts and a sheet of polycarbonate. We switched from flat belts to timing belts for ease of manufacturing, and because the timing belts seemed to have more consistent grip on the ball based on our tests.

In the first iteration of the one-sided design, the corner was curved 1/16” polycarb, but then was changed to bent 1/8”. This is just because we have a lot more 1/8” than 1/16”, and our press brake is convenient to use.

The other addition is mecanum wheels on the outer shaft. The jury’s still out on how much these actually help center the balls, but they don’t seem to hurt, and we do have a lot of 3D printed ones from 2020.

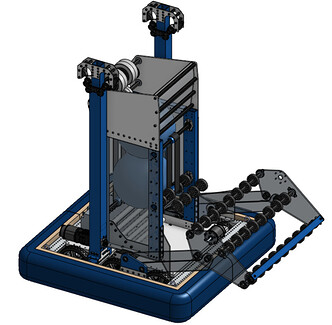

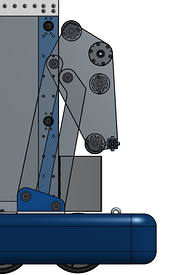

We also added this assembly at the top, which serves to both power the conveyor and deploy the intake via a winch.

The Falcon 500 goes to the winch shaft, while the NEO 550 goes to the belts. The plates are symmetrical, which means we can just machine two of the same.

This is how the intake winch works. It’s a little weird, but I think it could be effective.

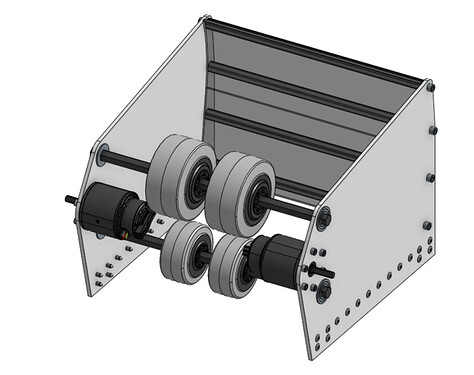

Shooter

The shooter has gone through many iterations, the main change being from a traditional hooded design to a dual-roller design. We believe this will give us more effective control over the backspin on the ball, making it easier to avoid bouncing out of the high goal.

Our original prototype from earlier in the week used two sets of 4” HiGrip wheels, with the lower wheels eventually being switched to 4” Colsons. However, based on other team’s tests (and many designs from 2020/21) we think that having smaller wheels on the top will lead to more consistent shots. We plan to order several 2.5” Colsons early week 3, and hopefully have those soon enough to do some more tests before we fabricate the final version.

We also got rid of the “accelerator wheel” after tests showed that slower feeding worked just fine for making the fender shot.

The shooter is powered by two 1:1 Falcon 500s. When we switched to the dual roller design, we originally thought to power both rollers from both motors. However, we realized that having the speeds independently controllable could give us much more control over backspin, and so now each roller is powered by one motor. Since we want our shooter to be able to make both the high and low shots, ideally both from the Fender, being able to control spin could make that a lot easier to pull off.

Some Thoughts on Strategic Design

A major focus of my design philosophy is “raise the floor before you raise the ceiling”. In FRC, consistency is the key to success, no matter what level of competition you’re at. The best teams aren’t successful just because their robot’s ceiling is higher than yours or mine - they’re the best because their floor is higher than most teams’ ceiling. And at the district event level, more often than not, simple robots that can score consistently seed higher than flashy high-goal robots that can’t score reliable points and RP.

The phrase “build within your limits” has been said many times by many people much smarter than me. The problem, of course, is trying to balance between staying within limits and pushing them in order to be more competitive. This is especially true for teams like mine who can’t build a robot that can do everything, but can build a simple, effective robot really well if we put our minds to it.

What I’ve learned is that the key is to overreach smartly. Aim to push your limits, but always keep a strong, reliable concept within them to fall back on. This year, the Lower Hub and Mid Rung are something that every robot that makes eliminations, no matter how simple or how advanced, should be able to do. And so no matter how much we try to reach for the high goal or the traverse climb, our first priority has to remain on those two objectives. That’s our floor. And after that, the only way to go is up.

-Charlie Becker