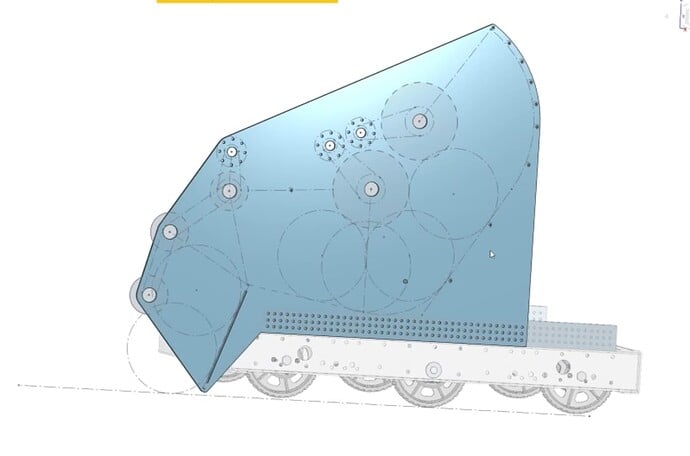

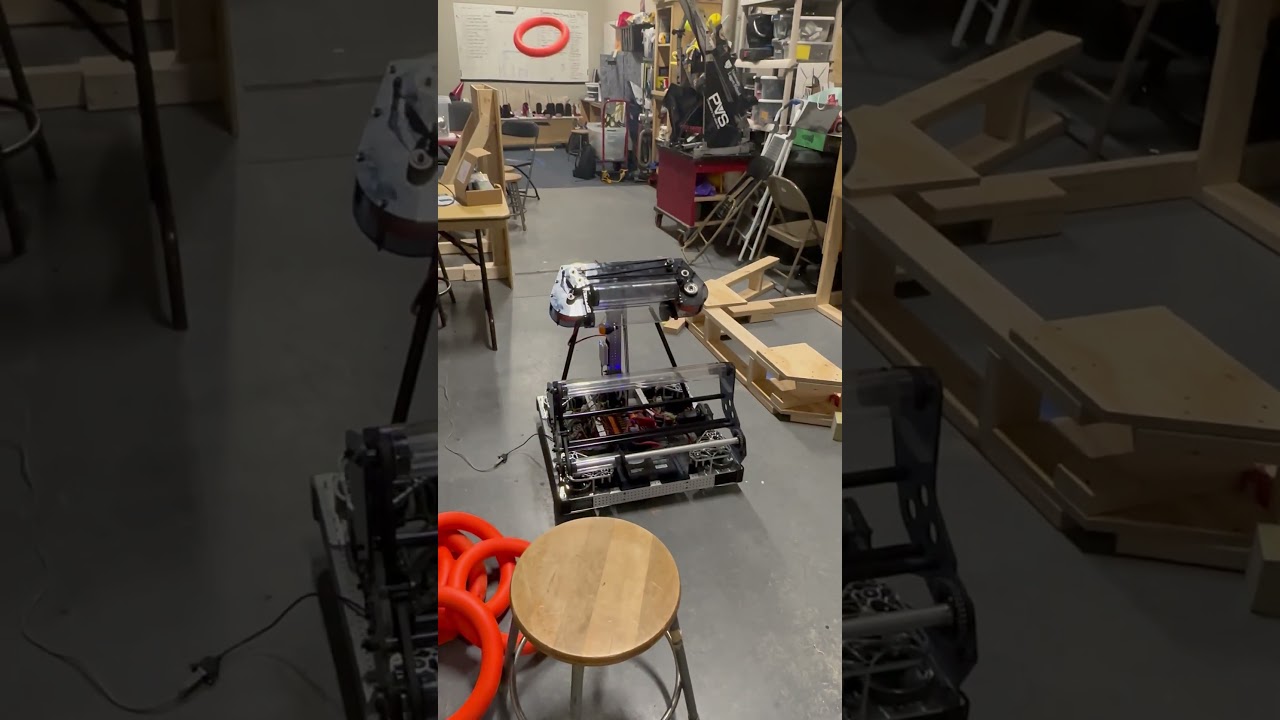

Initial Robot Tests

We officially have a moving robot! We learned a lot from these tests and found that a lot of things need to change. At the end of this post I will list some important lessons that we learned, many of which have to do with this specific architecture. If your team is using an architecture similar to this one, definitely keep those things in mind.

Speaker

First and most importantly, when we started shooting into the speaker, we found that our hardstop shooter angle was slightly too low. The notes hit the top of the speaker and miss about 20% of shots due to this. We put the robot on blocks to adjust the angle by about 2 degrees and this fixed the issue entirely.

Speaker shooting video without blocks:

Speaker shooting video with blocks:

We also tested shooting from the side of the subwoofer. This was a little bit particular based on position, but when the corner of our bumper is roughly aligned with the corner of the subwoofer, it works pretty well.

Although we hoped that the first set of shooter wheels would vector the note towards the center of the robot enough to not need our intake to center game pieces, this unfortunately creates too much spin and the notes don’t shoot accurately. This will be fixed with either an automated centering sequence (shown below) or some centering plates in the intake.

Finally, we found that this angle (adjusted by 2 degrees from blocks) works for about a foot back from the subwoofer. Once we change the hardstop angle and get controls tuned in we’ll do some more distance testing.

Amp

The one thing that we had no issues with when testing was the amp. Here is a video of our first attempt scoring in the amp:

Intake and Handoff

Overall the intake has a few small and easily fixable issues. First, the intake sometimes compresses the note too far and spits it out between standoffs. This should be fixed pretty quickly with another hardstop that we haven’t fully figured out yet

We also found that polycarb rollers don’t have enough grip on the note, which we somewhat expected. We will do more testing after adding some undecided form of grip tape to these rollers and post videos.

Finally, the handoff from intake to shooter doesn’t work from as many variable angles as we expected it to. We believe this is because the note hits a piece of polycarb between the two shooter plates which slows it down and makes the notes unstable in the air. The front shooter wheels and passive polycarb rollers also don’t hold the note well enough to stay in place while the shooter is moving. Both of these issues will be fixed with new shooter plates in the next week or so.

Controls

We spent a few hours yesterday beginning to tune in controls. The shooting sequence works effectively with what we currently have (basic closed loop control) but we plan to add motion profiling on several subsystems once revision 2 of this robot is complete. Our code is always public on our Github, but keep in mind that most of it is unfinished and unrefined. Here’s a video of the robot with a little more automation and closed loop control:

Next Steps

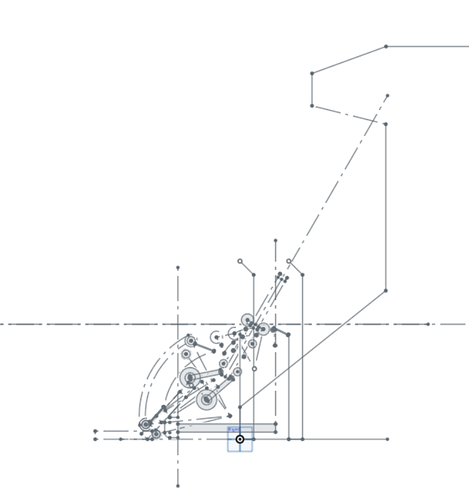

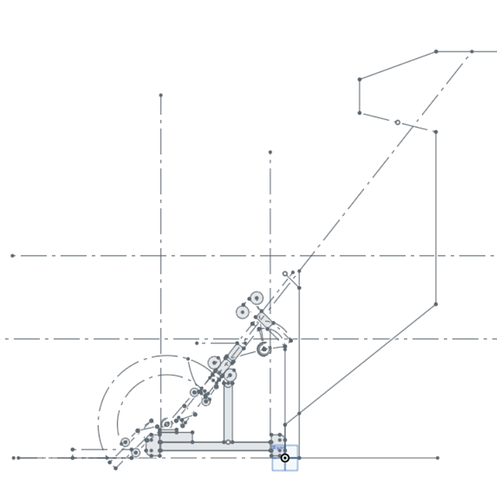

- We are spending practice today replacing shooter and intake plates to change the angle of the shooter. Unfortunately because of the precision of the handoff, most of the plates on this robot have to be replaced to make this small change.

- Our Krakens should be arriving early next week so we plan to mount those after plates are replaced

- The climber build is underway and will likely be mounted early next week as well

- This is a lower priority change, but at some point late next week we will be replacing the main shooter plates to increase compression on the note in the passive rollers to hold it better and remove the polycarb that is prohibiting variable shooting angles. (we are also changing our shooter wheels to black stealth wheels to match the aesthetic)

TLDR: Most Important Lessons Learned (and notes for teams building a similar architecture)

- The biggest downside of this robot architecture is that every time we want to make a small change in the intake or shooter angle, 4 pairs of plates need to be changed because both the intake and shooter need to change. This is detrimental to iteration because we plan to use our limited time between events to make as many robot improvements as possible, and this small change will require much more time than it would with a regular shooter.

- Shooting when the note is not centered in the intake creates too much spin and doesn’t work as well as we would like. There are ways around this, but it is something important to note.

- So far from our testing, shooting when the shooter and intake angles are not directly lined up from each other is inaccurate. This is probably due to something specific to our robot, so we will report back if/when we get this working once changes are made, although this is lower priority for the time being.

Overall we are very happy with the data we collected from these tests and will report back after this first round of iteration. As always, please feel free to post questions below!

Bonus content: attempted trap shooting

We spent a little while attempting to shoot into the trap and after testing countless positions and angles, we could not get it to successfully land. We have determined trap shooting as currently not worth our time, although if anything changes with robot revisions we will post here.

Trap shooting attempt: IMG_9226.MOV - Google Drive