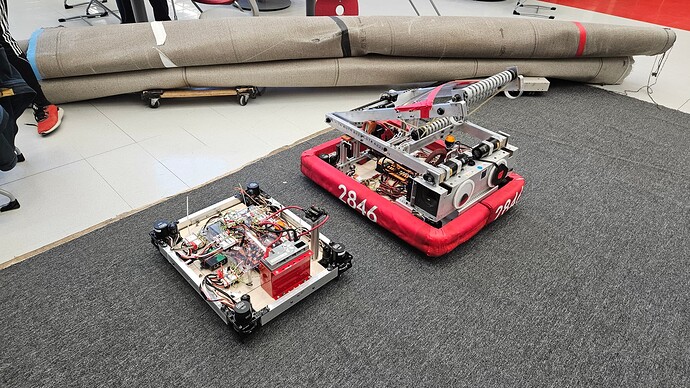

Welcome to the 2024 build thread for FRC team 2846, FireBears! We are excited to participate in Open Alliance for the first year.

About us:

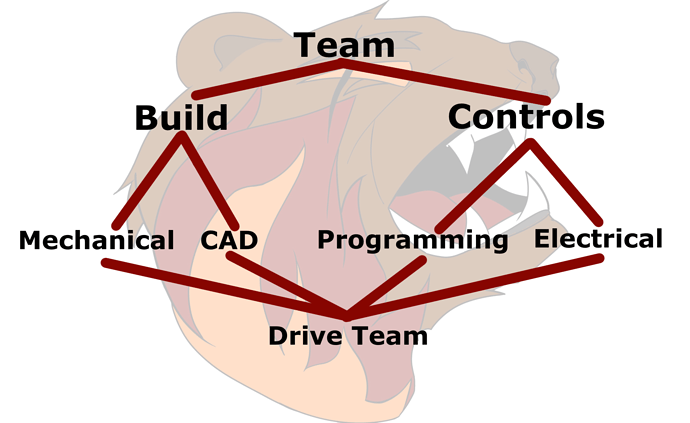

First competing in 2009 this is our 15th season. Operating out of Roseville Minnesota, we are currently a team of 40 students and 9 mentors. Broken up into 2 subteams; build and controls. Then in each subteam, students specialize in one of two areas. Either cad and mechanical for build or electrical and programming for controls. This allows for some training in each subteam, then more specialized training for the different areas of the subteam.

Build:

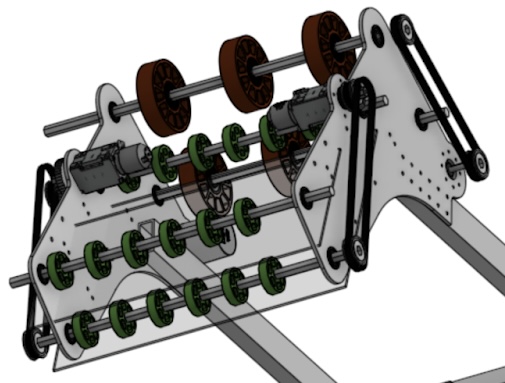

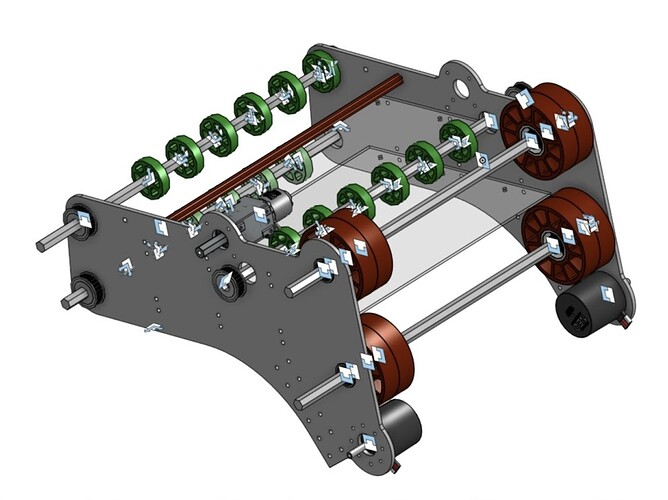

Currently our build subteam is using Onshape. Though we have just switched in the offseason from Solidworks. They have been working to refine a swerve drivetrain and create odds and ends. In addition all new build students were trained on our different power tools; mills, bandsaw, drill press, drills, and chop saw. With the returning students building a swerve drive base for 2023, early in the fall.

CAD links: Onshape

Onshape

To

Controls:

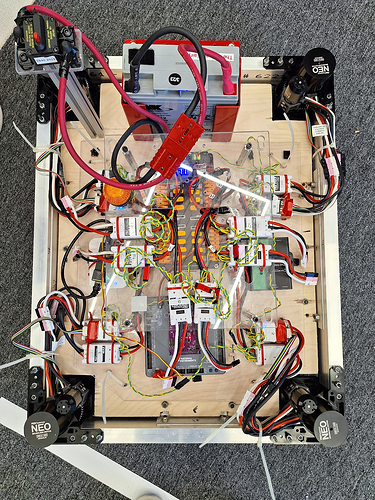

Lately the controls team has been working on updating our code for the 2023 robot from tank drive to swerve. They also have done training sessions for all programing focused students to get the new students up to speed but also to fill in gaps for returning students. While the electrical focused students have been either learning/reviewing how to stripe, crimp, and more. With the returning students also creating a new electrical board for the 2023 robot.

Outreach:

With the goal of increasing awareness, accessibility and acceptance of STEM we do numerous outreach efforts. Some of the biggest ones are:

-

Gold Tier Partner of LGBTQ+ of FIRST organization: As a team we are working to spread awareness and acceptance of the LGBTQ+ community in FIRST. Through presentation, booths at tournaments, promotion in our pit and more we strive to create a more inclusive environment in the FIRST community.

-

Minnesota Robotics Invitational (MRI): This is an offseason competition that we run in October. With 36 teams participating, it’s a great place for new drivers, while still being competitive.

-

Lego Robotics Camp: This fall we ran a 4 day camp after school for 12 1st-3rd graders. Using an old FLL game they worked in small groups to build a mechanism that could complete a task on the field.

Goals for 2024:

As we prepare for the upcoming season we have set several goals.

-

⅔ rule. Meaning we want the robot to be able to contribute ⅔ or more of what is needed to achieve all ranking points. This includes auto, teleop, and endgame.

- Ex: for 2023 this meant 8 game pieces and being able to balance in auto as well as endgame

-

Don’t over complicate it. Meaning design a robot that is somewhat simple. Still make it fast, and competitive.

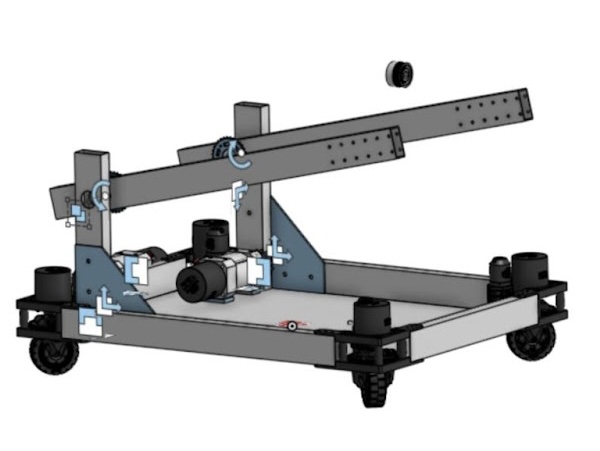

- Ex: Last year we went with a two linkage arm design, with the Everybot intake. There were only two joints to worry about and just a wheeled intake. With it being able to score 5 pieces as a tank drive and 7-9 with swerve.

- Ex: Last year we went with a two linkage arm design, with the Everybot intake. There were only two joints to worry about and just a wheeled intake. With it being able to score 5 pieces as a tank drive and 7-9 with swerve.

-

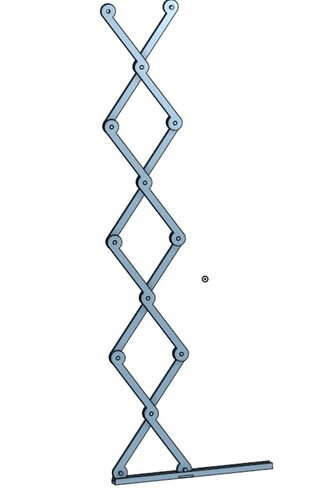

Make it easily repairable. Meaning all parts of it should be able to be quickly taken off and fixed/replaced. In addition, you can see electronic components for quicker diagnosis work.

- Ex: Last season the whole arm could be removed with 10 accessible screws, and the wiring had several disconnect points so you can not only quickly remove parts/subsystems but also wouldn’t have to rewire whole systems, just small sections.